Automatisierung für

komplexe Anlagen

Mehr Prozesssicherheit

Energieeffizienz und

Anlagenstabilität.

Zukunftssichere Automatisierung für Maschinenbauer und industrielle Unternehmen

AviComp steht für intelligente und zuverlässige Automatisierung. Wir verbinden technische Präzision mit tiefem Prozessverständnis – für höhere Sicherheit, effizienten Ressourceneinsatz, transparente Maschinenzustände und nachhaltigen Betrieb.

Von Regelungs- und Überwachungssystemen über Engineering bis zu digitalen Lösungen begleiten wir unsere Kunden mit fundiertem Know-how über den gesamten Anlagenlebenszyklus.

Maßgeschneiderte Lösungen mit umfassender Expertise für anspruchsvolle Projekte

Unsere Steuerungssysteme ermöglichen maximale Prozessstabilität und nahtlose Integration

Prozessoptimierung steigert die Energieeffizienz und senkt Betriebskosten

Online Monitoring hilft Ausfallzeiten zu vermeiden und potenzielle Störungen frühzeitig zu erkennen

Breite Kompetenz für anspruchsvolle Projekte

Extruder

Integrierte Steuerungs- und Überwachungssysteme für anspruchsvolle Extruderanlagen erhöhen die Betriebssicherheit und Effizienz. Unsere Lösungen sind individuell auf die jeweiligen Prozesse abgestimmt und vorab virtuell getestet.

Industrielle Automatisierung

Umfassendes Engineering, hohe Tool-Kompetenz und plattformübergreifende Umsetzung mit Systempartnern wie Siemens und Rockwell. Projektbegleitung von der Basisplanung bis zur Inbetriebnahme.

Industrial Service

OEMs, EPCs und Betreiber profitieren von unserem umfassenden Verständnis für komplexe Anlagen. Durch technische Expertise und prozessorientiertes Vorgehen werden Anlagenanforderungen bedarfsgerecht umgesetzt.

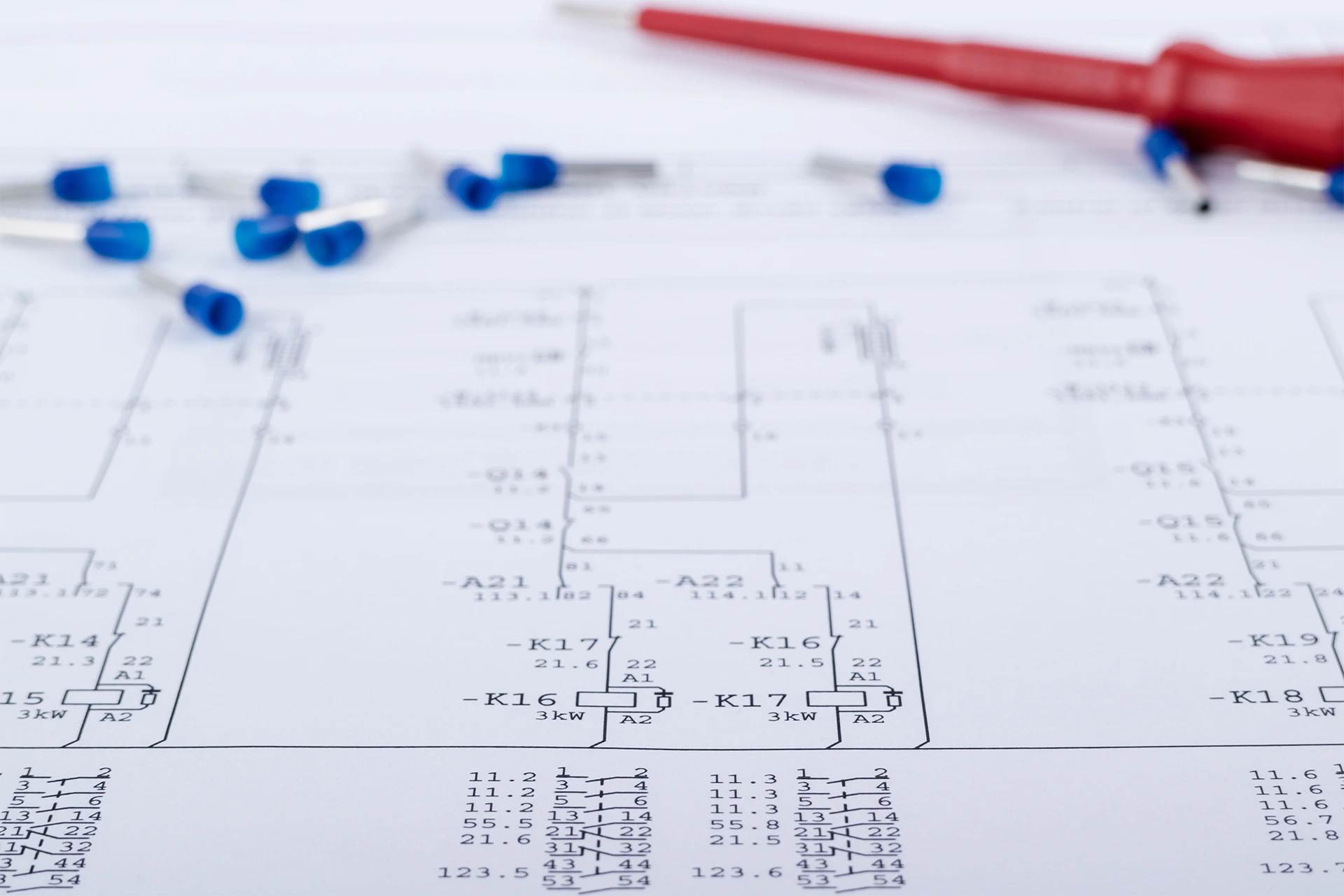

Engineering

Engineering-Services für den gesamten Projektzyklus: von Basic- und Detail-Engineering bis zur Umsetzung von Hard- und Softwarelösungen. Inklusive Systemdesign, Instrumentierung sowie Skid-Installation und -Verdrahtung.

Unsere Produkte

Unsere einzigartige Kombination aus eigener Entwicklung, Systemintegration und Prozesskompetenz gewährleistet, dass unsere Lösungen genau auf Ihre industrielle Anwendung zugeschnitten sind.

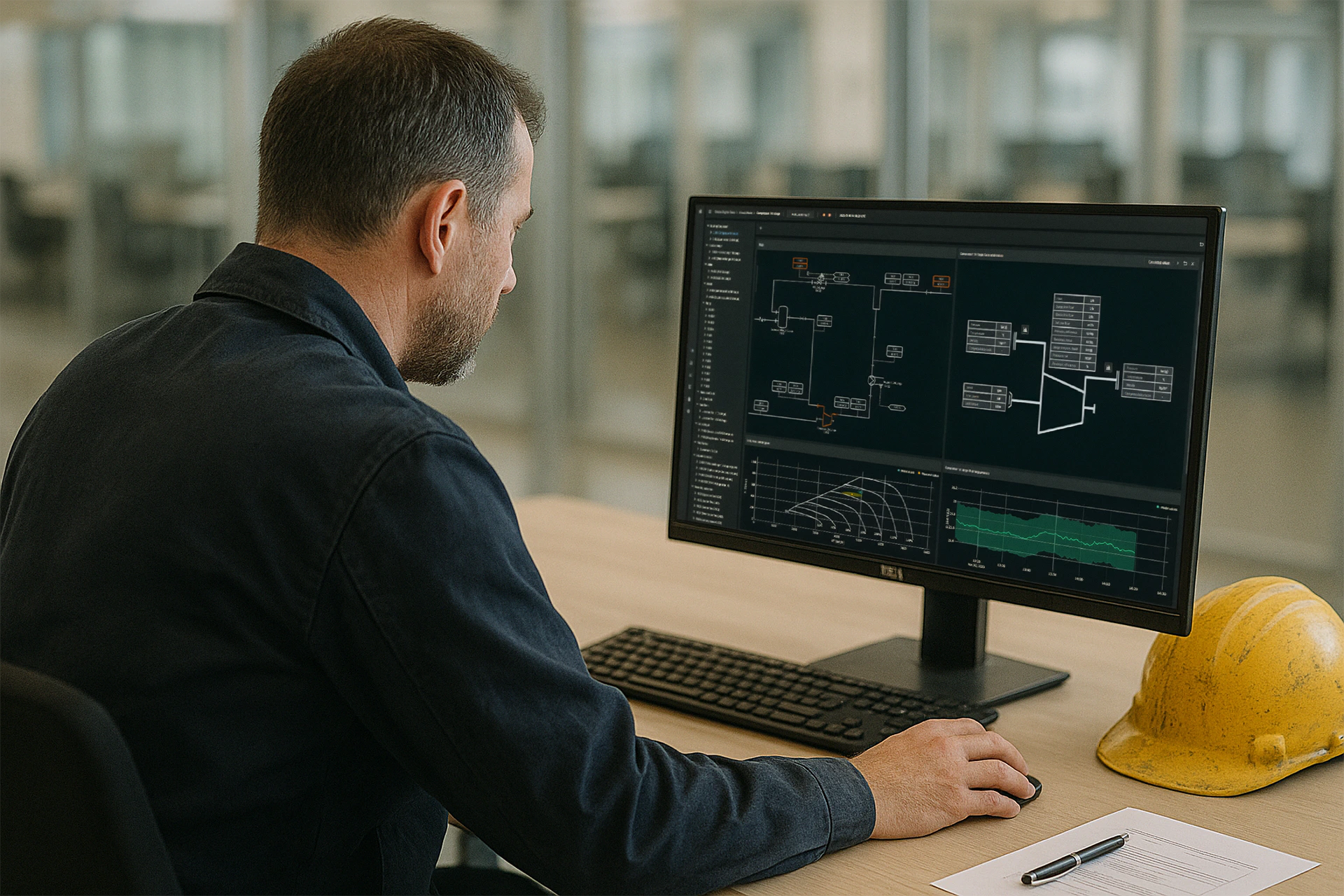

Digitaler Zwilling

Der Digitale Zwilling verbindet Daten, Modelle und Betriebserfahrung zu einem virtuellen Abbild Ihrer Anlage. So lassen sich Abweichungen frühzeitig erkennen, technische Änderungen gefahrlos testen, Effizienzpotenziale erkennen und Kosten senken – entlang des gesamten Anlagenlebenszyklus.

Zustandsüberwachung

Unser CCM System bietet hochauflösende Zustandsüberwachung und bewährte Schutzfunktionen für rotierende Maschinen. Störungen werden erkannt, bevor sie zum Ausfall führen – für mehr Sicherheit, maximale Verfügbarkeit, verbesserte Wartungsplanung und längere Lebensdauer Ihrer Assets.